Renting a suction dredge can be a practical and efficient solution for industries that require sediment removal, mining, or underwater excavation. Suction dredge rental offers flexibility, especially for short-term or project-specific needs, eliminating the hefty investment associated with purchasing equipment outright. Whether managing a construction site, maintaining a harbor, or extracting valuable minerals from riverbeds, renting the right dredging equipment allows businesses to meet their operational goals without long-term financial commitment. Additionally, choosing between standard suction dredges and more robust cutter suction dredgers depends on the specific project requirements, such as sediment type and dredging scale.

However, to maximize the benefits of suction dredge rental, it’s crucial to understand the types of dredges available, key factors to consider before renting, and the potential challenges you may encounter during dredging operations. From managing equipment costs and maintenance responsibilities to ensuring compliance with environmental regulations, thorough planning is essential. This guide provides practical insights to help businesses make informed decisions when renting suction dredges, covering everything from selecting the right equipment to implementing best practices for efficient and sustainable dredging..

Understanding Suction Dredge Rental

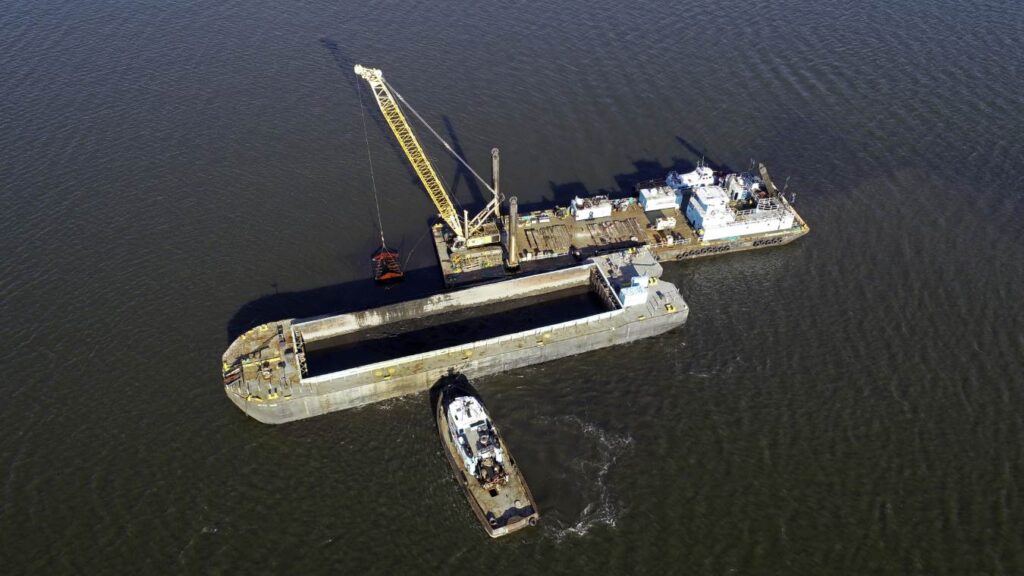

Suction dredge rental is a practical choice for industries that need to remove sediment, slurry, or debris from water bodies. A suction dredge works by using a powerful vacuum to suck up sediment and water, which are then transported through a pipeline to a designated discharge area. This method is efficient for maintaining waterways, cleaning ports, and extracting minerals from underwater deposits.

There are two primary types of suction dredges: standard suction dredges and cutter suction dredgers. A standard suction dredge is typically used for softer sediments and is ideal for maintaining canals, lakes, or shallow water bodies. On the other hand, a cutter suction dredger is equipped with a rotating cutter head that loosens compacted materials like clay or dense sand before suction. This makes cutter suction dredgers more versatile for tougher dredging tasks, including land reclamation and mining projects.

Opting for a suction dredge rental rather than purchasing offers several benefits, especially for short-term or project-specific needs. Renting significantly reduces capital investment and eliminates long-term maintenance and storage concerns. Additionally, renting allows companies to select the right dredge model for each project, whether a standard suction dredge for softer materials or a cutter suction dredger for more challenging terrains. This flexibility ensures that businesses can adapt to various operational requirements without the financial commitment of ownership.

Common applications for suction dredge rental include mining, sediment removal from rivers or reservoirs, harbor maintenance, and construction projects where sediment displacement is necessary. In the mining sector, dredges help extract valuable minerals from riverbeds, while in construction, they play a critical role in site preparation and land development. By choosing to rent rather than buy, companies can efficiently manage costs while utilizing advanced dredging technology tailored to specific project demands.

Types of Suction Dredges Available for Rental

When opting for suction dredge rental, it’s essential to understand the different types available and their specific applications. Choosing the right dredge for your project can significantly impact operational efficiency and cost management. Below are the primary types of suction dredges available for rental, each suited for different project requirements.

1. Standard Suction Dredge

A standard suction dredge is commonly used for projects involving shallow waters and softer sediments. These dredges are designed to efficiently remove silt, mud, and fine sand from water bodies, making them ideal for tasks like canal maintenance, small pond cleaning, and sediment removal from shallow reservoirs.

- Best for: Shallow waters, small-scale sediment removal

- Features: Simple operation, lower power requirements, compact size

- Typical Use Cases: Canal dredging, small-scale sediment management, maintenance of water features

2. Cutter Suction Dredger

A cutter suction dredger (CSD) is a more robust machine equipped with a rotating cutter head that breaks up hard, compacted soils before suction. This feature makes it suitable for large-scale dredging projects where materials like clay, gravel, or compacted sand need to be excavated.

- Best for: Hard, compacted soils, large-scale dredging

- Features: Powerful cutter head, higher capacity, suitable for challenging environments

- Typical Use Cases: Land reclamation, mining, harbor deepening, dredging in compacted sediment areas

3. Portable Dredges

Portable suction dredges offer flexibility for projects requiring frequent relocation. These lightweight and easily transportable dredges are ideal for small-scale projects and quick interventions where mobility is crucial. They are designed to be set up with minimal effort and are often used for temporary sediment management or emergency cleanup.

- Best for: Temporary or small-scale dredging, rapid deployment

- Features: Lightweight, easy to assemble and transport, minimal maintenance

- Typical Use Cases: Emergency dredging, small lake maintenance, localized sediment removal

Comparison of Features and Capabilities

When choosing a suction dredge rental, it’s essential to consider the specific project requirements. While standard suction dredges are excellent for smaller, softer sediment projects, cutter suction dredgers are necessary for tackling more substantial and compacted soil challenges. Portable dredges, on the other hand, provide the advantage of mobility, making them practical for dynamic environments.

- Efficiency: Cutter suction dredgers offer superior efficiency in hard terrains, while standard suction dredges are more economical for soft sediment removal.

- Mobility: Portable dredges offer quick setup and mobility compared to stationary dredging units.

- Project Scale: Cutter suction dredgers are more suitable for large-scale industrial projects, whereas standard suction dredges and portable units are better for smaller or short-term tasks.

Selecting the right type of suction dredge rental is crucial for optimizing project outcomes. Evaluating the nature of the sediment, project duration, and mobility requirements will help determine the best dredge type for your needs.

Key Factors to Consider Before Renting

Choosing the right suction dredge rental for your project requires careful evaluation of several factors to ensure efficient and cost-effective operations. Understanding these key considerations will help you select the most suitable equipment and avoid unnecessary complications.

1. Project Requirements

Before renting a suction dredge, assess the specific requirements of your project, including its duration, location, and the type of material you need to remove. Projects with soft sediments, such as silt and mud, may only require a standard suction dredge, while compacted soils or rocky materials might necessitate a cutter suction dredger.

- Duration: Determine whether the project is short-term or long-term, as rental costs vary accordingly.

- Location: Consider site accessibility and environmental conditions.

- Material Type: Identify the sediment composition to choose between standard dredges and cutter suction dredgers.

2. Equipment Size and Capacity

Matching the dredge size to the project scope is essential to maintain efficiency. An undersized dredge might prolong the project, while an oversized unit could increase costs without added benefits.

- Capacity Requirements: Calculate the volume of sediment to be removed and the dredging depth.

- Power and Suction Capability: Choose equipment that can handle the material density and removal rate needed.

- Versatility: For projects requiring both soft and compacted sediment removal, a cutter suction dredger may be more appropriate.

3. Mobility and Portability

Some projects demand quick relocation and easy setup, making portable dredges the ideal choice. Conversely, larger and more powerful cutter suction dredgers might be more suited for fixed, long-term dredging sites.

- Ease of Transportation: Check whether the dredge can be easily moved between sites.

- Setup Complexity: Opt for dredges that can be rapidly deployed if the project requires frequent site changes.

- Site Constraints: Consider factors like narrow waterways or limited docking areas when choosing between stationary and portable dredges.

4. Operator Skill Level

Not all suction dredge rentals come with an operator, so you may need to hire trained personnel. Some models, especially cutter suction dredgers, require skilled operators to handle complex tasks and maintenance.

- Skill Requirements: Assess whether your team has experience with the chosen dredge type.

- Training Availability: Check if the rental company offers operator training.

- Safety Protocols: Ensure that operators are knowledgeable about safety measures, especially when handling more advanced equipment.

5. Environmental Considerations

Using a suction dredge can impact the local environment, especially in sensitive ecosystems or regulated waterways. Compliance with environmental regulations is crucial to avoid legal issues and project delays.

- Regulatory Compliance: Research local and federal guidelines regarding dredging activities.

- Sediment Disposal: Plan for the safe and legal disposal of dredged materials.

- Minimizing Impact: Choose eco-friendly dredging methods to reduce disruption to aquatic habitats.

- Noise and Emission Controls: Opt for models equipped with noise reduction and lower emission features.

Carefully considering these factors before choosing a suction dredge rental will help ensure a smooth and efficient operation, minimizing both environmental risks and project costs. Selecting the right equipment based on your specific needs will optimize performance and maximize productivity.

Cost Breakdown of Suction Dredge Rentals

When planning a suction dredge rental, it’s essential to understand the various costs involved to ensure accurate budgeting. Different factors can influence the overall expenses, from rental fees to insurance coverage. Here’s a breakdown of the primary cost components to consider.

1. Rental Fees

Rental costs for a suction dredge can vary significantly based on the type of dredge, rental duration, and the provider’s pricing structure. Generally, rental fees are charged on an hourly, daily, or weekly basis.

- Hourly Rates: Suitable for short-term or emergency dredging tasks, where the project duration is minimal.

- Daily Rates: Ideal for projects lasting a few days, providing a cost-effective solution without committing to long-term rental.

- Weekly Rates: Recommended for extended operations, offering better value compared to daily charges.

- Cutter Suction Dredger Fees: Typically higher than standard suction dredges due to their enhanced capabilities and larger size.

- Variable Pricing: Costs may fluctuate based on peak seasons or high-demand periods.

2. Maintenance Costs

Routine maintenance is crucial to keep the suction dredge operational during rental. It’s important to clarify whether maintenance responsibilities fall on the renter or the rental company.

- Included Maintenance: Some rental agreements cover basic maintenance, such as lubrication and routine checks.

- Renter-Managed Maintenance: In some cases, the renter must handle daily upkeep, including cleaning and minor repairs.

- Major Repairs: Clarify who bears the cost if the equipment breaks down or needs significant repair during rental.

- Cutter Suction Dredger Maintenance: Due to their complexity, these dredgers may require more frequent inspections and specialized maintenance.

3. Transport and Setup Fees

Transporting a suction dredge to the project site can incur significant costs, especially if the site is remote or difficult to access.

- Transportation Charges: Often based on distance, equipment size, and logistics requirements.

- Setup Costs: Some dredges, like cutter suction dredgers, require professional assembly or calibration, which can add to the setup expenses.

- On-Site Adjustments: Additional costs may arise if the dredge needs to be repositioned during the project.

- Portable Dredge Advantage: Smaller, portable models generally have lower transport and setup fees compared to larger, fixed units.

4. Operator Charges

Not all suction dredge rentals include skilled operators. If the rental does not come with an operator, hiring a trained professional can add to the overall cost.

- Hourly Operator Fees: Depending on experience and certification, operators can charge per hour or project.

- Cutter Suction Dredger Expertise: Due to the technical nature of these dredgers, certified operators may command higher wages.

- Training Costs: If the rental provider offers training for your team, it may come at an additional fee.

- Safety and Compliance: Ensuring that operators follow safety protocols is crucial, especially with high-capacity equipment.

5. Insurance and Liability

Accidents or equipment damage during dredging can result in costly repairs or liability issues. Therefore, having adequate insurance coverage is essential when opting for a suction dredge rental.

- Liability Coverage: Protects against accidents caused by equipment failure or operator error.

- Damage Insurance: Covers repairs if the dredge is damaged during use.

- Theft and Loss Protection: Particularly important if the dredge is stationed in unsecured or remote areas.

- Cutter Suction Dredger Insurance: Higher premiums may apply due to the dredger’s value and complex components.

- Rental Agreement Clauses: Review the terms carefully to understand who is responsible for insurance and what types of coverage are mandatory.

By thoroughly evaluating these cost components, businesses can make more informed decisions about suction dredge rental and ensure that all potential expenses are accounted for before the project begins. Proper planning helps manage budgets effectively and reduces unexpected financial burdens.

Tips for Renting a Suction Dredge

Securing the right suction dredge rental is critical for the success of your dredging project. From choosing a reputable supplier to ensuring operator safety, following these tips can help you maximize the efficiency and safety of your rental process.

1. Choosing a Reliable Supplier

Finding a trustworthy supplier is essential for a smooth rental experience. Reputable companies provide well-maintained equipment and responsive customer support, reducing the risk of downtime.

- Reputation Check: Look for reviews, ratings, and testimonials from other customers.

- Service Quality: Inquire about the availability of technical support during the rental period.

- Supplier Experience: Prefer suppliers with extensive experience in suction dredge rental and a good track record of delivering reliable equipment.

- Specialized Equipment: Ensure the supplier can provide both standard suction dredges and cutter suction dredgers if needed.

2. Inspecting the Equipment

Before finalizing the rental, thoroughly inspect the dredge to ensure it meets your project requirements. Proper inspection helps identify potential issues and avoid operational delays.

- Physical Inspection: Check for visible signs of wear, corrosion, or damage.

- Operational Testing: Run the dredge to verify suction power and cutter head efficiency (if renting a cutter suction dredger).

- Performance Records: Request recent maintenance logs to ensure the dredge has been serviced properly.

- Safety Features: Confirm the presence of essential safety systems like emergency stops and operator protection.

3. Maintenance Records

Verifying the maintenance history of the suction dredge ensures that you are renting well-maintained equipment capable of handling your project demands.

- Service History: Request records of recent maintenance, including engine checks and dredge pump servicing.

- Repair Logs: Check if the equipment has had frequent repairs, which might indicate recurring issues.

- Preventive Maintenance: Ask about routine upkeep practices, such as lubrication and component replacements.

- Special Consideration for Cutter Suction Dredgers: Due to their complex cutter heads, these dredgers require more frequent maintenance. Ensure that recent servicing has addressed cutter blade conditions and suction pipe integrity.

4. Rental Agreement Details

Understanding the rental contract thoroughly helps avoid unexpected charges or disputes during or after the rental period.

- Terms and Conditions: Carefully review clauses regarding equipment damage, maintenance responsibilities, and return conditions.

- Insurance Coverage: Confirm that the agreement includes liability protection and equipment damage coverage.

- Operational Limits: Be aware of any usage restrictions that might void the rental warranty.

- Cancellation Policy: Check for penalties associated with early termination or extension of the rental period.

- Cutter Suction Dredger Specifics: Due to their advanced nature, some agreements may include clauses about skilled operator requirements or mandatory safety checks.

5. Training and Safety Precautions

Proper training is vital to ensure the safe and efficient operation of suction dredges, particularly more complex models like cutter suction dredgers.

- Operator Certification: Ensure that operators have relevant certifications or training on the specific dredge model.

- Supplier-Provided Training: Some suppliers offer training sessions as part of the rental package.

- Safety Gear: Provide personal protective equipment (PPE) such as helmets, gloves, and high-visibility vests for all personnel involved.

- Safety Protocols: Familiarize operators with emergency procedures and safety features, including the use of cutoff switches and pressure monitoring systems.

- Regular Safety Briefings: Conduct daily briefings to discuss potential risks and safety measures during dredging operations.

By following these tips, businesses can optimize their suction dredge rental process, ensuring that the equipment is reliable, safe, and well-suited to the project at hand. Taking the time to assess each aspect of the rental process will help achieve efficient, trouble-free dredging operations.

Common Challenges and How to Overcome Them

Opting for suction dredge rental can streamline your project, but challenges may arise during dredging operations. Addressing potential issues proactively will help maintain productivity and minimize downtime. Here are some common challenges encountered while using suction dredges and cutter suction dredgers, along with practical solutions.

1. Equipment Malfunction

Unexpected breakdowns can disrupt the entire dredging operation. Malfunctions may occur due to mechanical failures, clogged pumps, or worn-out parts, especially in complex machinery like cutter suction dredgers.

- Backup Plans: Have a secondary dredge or alternative equipment on standby to minimize delays.

- Maintenance Support: Choose a suction dredge rental provider that offers prompt technical assistance or on-site repair services.

- Spare Parts Inventory: Keep essential spare parts, such as pump components and cutter head blades, readily available.

- Preventive Maintenance: Conduct daily equipment checks to identify potential issues before they escalate.

2. Dredge Efficiency Issues

Reduced efficiency can occur when the suction power is insufficient or the cutter head fails to break up dense materials effectively. This is particularly relevant for cutter suction dredgers, which require precise adjustments.

- Adjusting Suction Power: Check the pump settings and suction line for blockages. Increase the power gradually to prevent overloading.

- Cutter Head Optimization: If the cutter is not breaking compacted soils effectively, sharpen or replace the blades. Adjust the rotation speed to match the sediment density.

- Flow Rate Monitoring: Continuously track the flow rate and make real-time adjustments to maintain optimal suction efficiency.

- Routine Calibration: Regularly calibrate the suction system to match project demands and sediment consistency.

3. Sediment Blockage

Blockages in the suction pipe or cutter head can significantly reduce performance. Fine particles, debris, or compacted materials can accumulate, obstructing the flow.

- Clearing Blockages: Stop the operation and flush the pipe system with water to dislodge trapped material.

- Cutter Head Cleaning: Manually remove debris from the blades, especially when using a cutter suction dredger.

- Sediment Management: Use a pre-screening system to filter larger debris before it reaches the suction intake.

- Regular Inspections: Frequently check the suction line and cutter head to detect any build-up early.

- Anti-Clogging Features: Invest in dredges with self-cleaning systems to reduce manual intervention.

4. Environmental Concerns

Dredging activities can impact local ecosystems, causing water turbidity, sediment dispersion, and habitat disruption. Adhering to eco-friendly practices is essential for minimizing environmental harm.

- Eco-Friendly Dredging Techniques: Use low-impact dredging methods that reduce sediment plumes and protect aquatic habitats.

- Sediment Containment: Employ silt curtains or barriers to limit the spread of disturbed materials.

- Cutter Suction Dredger Adjustments: Fine-tune the cutter speed to minimize sediment disruption while maintaining efficiency.

- Waste Management: Properly dispose of dredged materials following environmental regulations.

- Compliance Assurance: Regularly monitor water quality parameters such as turbidity and dissolved oxygen to ensure compliance with local environmental standards.

By proactively addressing these common challenges, businesses can maximize the performance of their suction dredge rental while minimizing operational disruptions and environmental impacts. Proper planning and ongoing monitoring are essential to maintaining productivity and ensuring responsible dredging practices.

Conclusion

Choosing the right suction dredge rental requires careful consideration of various factors, including project needs, equipment type, cost implications, and potential challenges. By understanding the differences between standard suction dredges and cutter suction dredgers, businesses can make well-informed rental choices that enhance project efficiency and reduce operational risks. Following best practices, such as inspecting equipment, verifying maintenance history, and providing proper operator training, will help ensure smooth and successful dredging operations. With the right planning and preparation, renting a suction dredge can be a strategic and cost-effective approach to meeting your dredging needs.