In environments where abrasive solids like sand, gravel, tailings, and metal fines are present, choosing the right pumping solution is critical to maintaining operational efficiency and reducing downtime. A submersible slurry pump is specifically engineered to handle these harsh materials with minimal wear and maximum reliability. Whether powered hydraulically or electrically, these pumps offer unique advantages in industries such as mining, dredging, construction, and wastewater management. This article explores the core technologies behind submersible slurry pumps, compares hydraulic and electric models, and provides expert insights on selecting, maintaining, and optimizing pump performance for abrasive slurry applications.

The Role of Submersible Slurry Pumps in Handling Abrasive Solids

Abrasive solids are a common challenge in various industrial pumping applications. These materials include sand, gravel, coal fines, crushed ore, tailings, and metallic particles. Their coarse and angular nature causes rapid wear and tear on standard pumps not designed to handle such harsh media. In high-solid environments, traditional dewatering or centrifugal pumps often experience impeller erosion, clogged suction lines, and seal failures, leading to costly downtime and frequent maintenance.

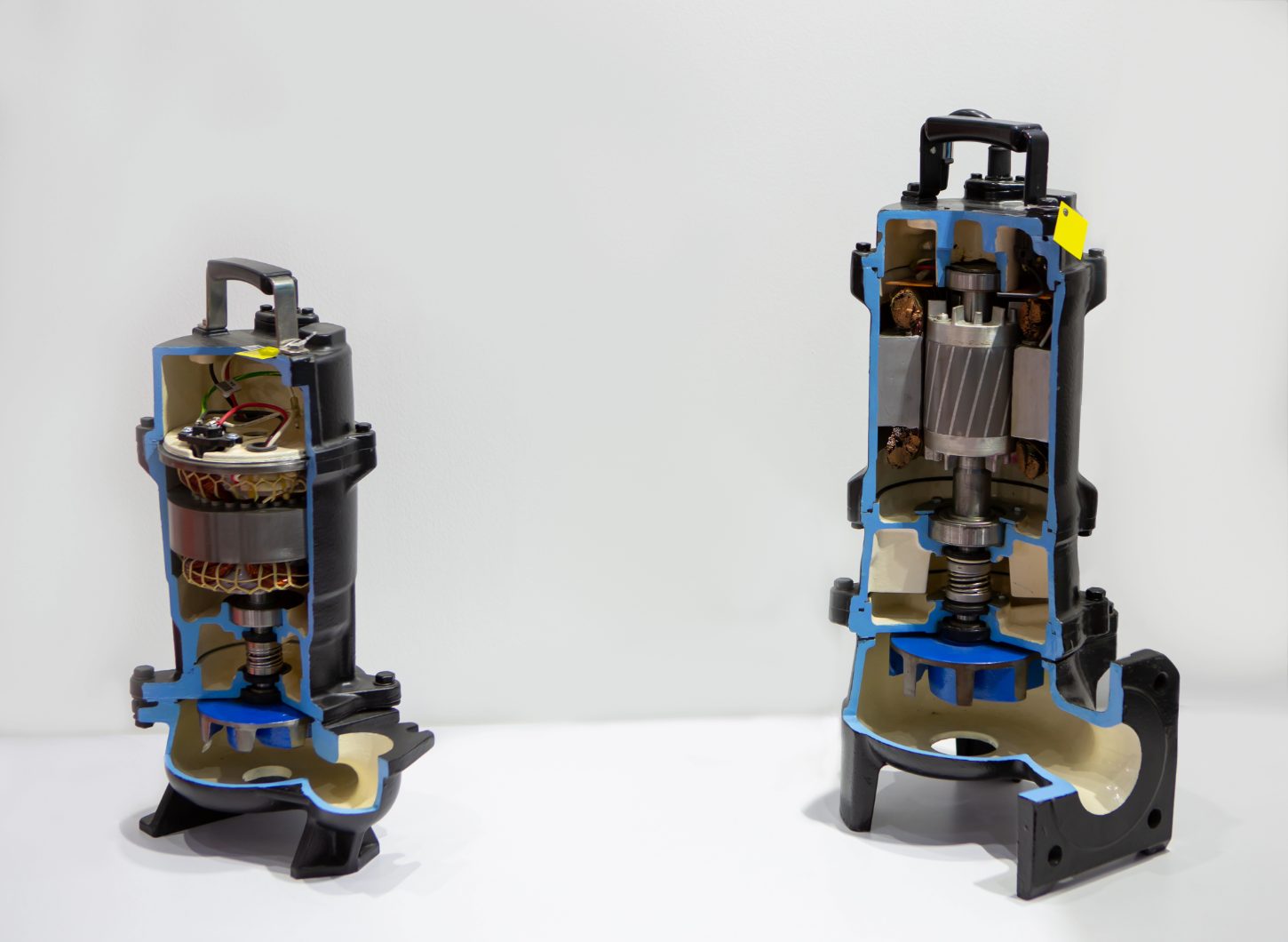

A submersible slurry pump is specifically engineered to overcome these challenges. Unlike conventional surface-mounted pumps, a submersible slurry pump operates while fully immersed in the slurry. This direct submersion eliminates the need for a suction lift, reducing energy loss and preventing air binding or cavitation. The pump’s impeller is located close to the slurry source, ensuring consistent material intake and more stable performance even in highly viscous or sediment-rich fluids.

Compared to other pump types, both hydraulic submersible slurry pumps and electric submersible slurry pump designs are built with robust components such as wear-resistant impellers, reinforced casings, and heavy-duty seals. These features allow them to move slurries containing high percentages of solids without clogging or damage. The hydraulic submersible slurry pump is often preferred for mobile applications and high-torque requirements, such as excavator-mounted dredging or mining operations. Meanwhile, the electric submersible slurry pump is ideal for stationary installations with steady power access and continuous operation needs.

The submersible configuration not only enhances operational efficiency but also simplifies setup by eliminating long suction pipelines. By being placed directly in the pumping zone, the submersible slurry pump minimizes head loss. It improves slurry transport performance, making it the pump of choice for abrasive and high-solid content applications.

Key Technologies That Make Submersible Slurry Pumps Effective

The efficiency and durability of a submersible slurry pump depend heavily on the advanced technologies built into its design. These features enable the pump to handle dense, abrasive slurries under tough conditions without frequent breakdowns or excessive wear.

Heavy-duty impeller designs are a core component of any submersible slurry pump. The choice between open and closed impellers plays a significant role in pump performance. Open impellers are preferred for handling large or fibrous solids as they offer wider passages and are less likely to clog. Closed impellers, on the other hand, are more efficient in transferring energy and are better suited for finer particles. Vane geometry is also critical, as the angle and spacing of the vanes are optimized to improve solids passage, reduce turbulence, and minimize blockages.

Agitators and cutter heads are additional technologies that enhance slurry handling. These attachments are typically found on a hydraulic submersible slurry pump. They are designed to break up settled solids, agitate thick slurries, and keep particles in suspension for more effective pumping. Agitators continuously stir the surrounding material, while cutter heads help dislodge compacted sediments such as clay, silt, or debris in dredging and mining operations.

Material selection is another key factor. Submersible slurry pumps often use high-chrome alloys and wear-resistant coatings for components like the pump housing, impellers, and liners. These materials offer exceptional resistance to abrasion, making them essential for operations involving sand, gravel, or metallic slurries. Using robust materials significantly reduces downtime and extends the lifespan of the pump.

To protect the internal components, especially in abrasive environments, double mechanical seals are used to prevent slurry ingress into the motor compartment. These sealing systems provide a secondary barrier in case the primary seal fails, ensuring continuous and safe operation. Seal protection systems may also include seal flush ports or pressure-compensating devices that extend seal life in high-pressure applications.

Cooling jackets and motor protection systems are particularly important in electric submersible slurry pumps, especially when operating in shallow or hot environments where motor overheating can occur. These jackets circulate surrounding fluid to dissipate heat, keeping the motor within a safe temperature range. Combined with thermal sensors and overload protection, these systems safeguard the pump against overheating and premature failure.

Comparing Hydraulic vs. Electric Submersible Slurry Pumps

When selecting a submersible slurry pump, one of the most important decisions is choosing between a hydraulic or electric configuration. Each type offers distinct advantages and limitations, and the right choice depends on the specific demands of the application and site conditions.

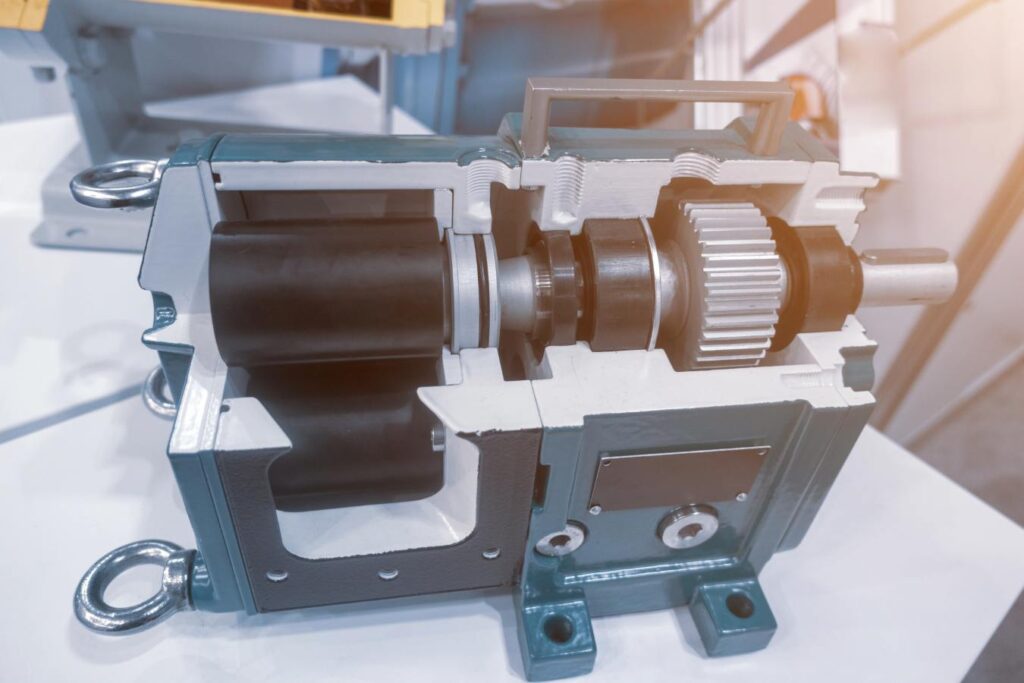

A hydraulic submersible slurry pump is driven by hydraulic power supplied from an external power pack or heavy machinery, such as an excavator or skid steer. These pumps are well-suited for mobile operations, remote job sites, and environments where electric power is not readily available. Their high torque output and compact design make them ideal for aggressive dredging, mining, and dewatering tasks. The hydraulic drive also allows for a wide range of flow and pressure control. However, hydraulic systems require additional equipment and setup, such as hoses, oil reservoirs, and control valves, which can increase complexity and maintenance requirements.

An electric submersible slurry pump operates using an integrated electric motor, making it more straightforward to deploy in fixed installations with consistent power access. These pumps are highly energy-efficient, quieter, and easier to automate with variable frequency drives and remote monitoring systems. They are commonly used in municipal wastewater treatment, process plants, and industrial pits where stable electrical infrastructure is present. The primary drawback of electric submersible slurry pumps is their limited mobility and vulnerability to power fluctuations, which can lead to overheating or shutdowns if not properly managed.

Choosing the right type of submersible slurry pump depends on several site-specific factors. Power availability plays a critical role—if grid electricity is accessible, electric models offer simplicity and efficiency. For off-grid or dynamic environments, hydraulic submersible slurry pumps provide the versatility and ruggedness required. Other considerations include the required mobility, submersion depth, and exposure to abrasive or corrosive materials. Matching the pump type to the operational context ensures reliable performance and reduced downtime.

Performance Factors That Influence Pump Efficiency

The efficiency of a submersible slurry pump is heavily influenced by how well it matches the operational demands of the application. Key performance factors such as solids handling capacity, flow rate, head pressure, resistance to cavitation, and energy consumption all play critical roles in determining how effectively the pump operates over time.

Solids handling capacity is one of the most important performance metrics for any submersible slurry pump. This includes the maximum particle size the pump can pass without clogging and the percentage of solids by weight it can handle effectively. Pumps used in mining, dredging, or dewatering often encounter slurries with high solid concentrations, so choosing a pump with appropriate impeller clearance and wear-resistant materials is vital. Both hydraulic submersible slurry pumps and electric submersible slurry pumps are available with high solids handling capabilities. Still, the right configuration depends on the specific material properties and operational environment.

Flow rate and total dynamic head must be carefully matched to the system’s requirements. The flow rate, typically measured in gallons per minute (GPM) or cubic meters per hour, needs to meet production targets. At the same time, the total dynamic head accounts for the vertical lift, pipe friction, and pressure losses in the system. Selecting a pump with a performance curve that aligns with these factors ensures consistent output and prevents overloading or inefficiency.

Cavitation resistance is another crucial consideration. Cavitation occurs when vapor bubbles form due to low pressure at the pump inlet, potentially causing severe damage to the impeller and internal components. To minimize this risk, the submersible slurry pump must be installed at the correct depth and positioned to ensure unobstructed intake flow. Proper submersion and suction-free operation are key advantages of both hydraulic submersible slurry pumps and electric submersible slurry pumps, as they reduce the chances of cavitation compared to dry-mounted systems.

Energy consumption directly impacts operational costs, especially for long-running applications. Efficient pumps balance power usage with the ability to move dense, abrasive slurries without stalling or overheating. Electric submersible slurry pumps often offer higher energy efficiency, especially when paired with variable frequency drives, while hydraulic submersible slurry pumps provide greater torque and adaptability for fluctuating load conditions. Choosing a pump that balances energy use with durability ensures optimal performance and lower lifetime operating costs.

Best Practices for Selecting the Right Submersible Slurry Pump

Choosing the correct submersible slurry pump requires a detailed assessment of both the slurry characteristics and the operating environment. Following best practices during the selection process helps ensure reliable performance, minimal downtime, and longer equipment life in abrasive and high-solid applications.

The first step is assessing the slurry composition. This includes evaluating particle size, hardness, density, and corrosiveness. Larger or sharper particles require a pump with wider impeller passages and heavy-duty components. Dense slurries increase wear on internal parts and demand greater torque, while corrosive elements necessitate chemically resistant materials. Both hydraulic submersible slurry pumps and electric submersible slurry pumps are available in configurations that can handle a wide range of slurry types. Still, the choice depends on the specific makeup of the pumped material.

Evaluating site conditions is equally important. The depth at which the pump will operate, the surrounding temperature, and the presence of chemicals or hydrocarbons all influence pump selection. Submersion depth affects the required head pressure and sealing mechanisms. High temperatures may demand additional motor cooling features, especially in electric submersible slurry pumps. Chemical exposure, such as from acids or salts, requires material compatibility to avoid rapid degradation. Accessibility for inspection and servicing is also a factor—remote sites may benefit more from a hydraulic submersible slurry pump with fewer electrical components.

Proper pump sizing is crucial. Flow rate (GPM), total dynamic head, and system pressure must align with the pump’s performance curve. Oversizing wastes energy and increases wear, while undersizing can result in insufficient output or system failure. Using manufacturer-provided performance data to match system needs with pump capacity ensures optimal efficiency.

Material selection plays a major role in durability and performance. High-chrome components are ideal for handling highly abrasive slurries. Rubber-lined or composite materials can provide impact resistance and chemical protection in less severe conditions. Matching the construction materials to the slurry type improves longevity and reduces the frequency of part replacement.

Finally, incorporating safety and monitoring features enhances long-term reliability. Variable frequency drives allow fine-tuned speed control in electric submersible slurry pumps, improving efficiency under varying loads. Pressure sensors help detect blockages or suction issues early. Thermal protection and seal monitoring add layers of defense against overheating or contamination, helping both hydraulic and electric submersible slurry pumps maintain safe, continuous operation in harsh conditions.

Common Pitfalls to Avoid

Avoiding common mistakes when selecting a submersible slurry pump is essential for ensuring efficient performance and long-term reliability. These pumps operate under harsh conditions, and overlooking key variables can lead to premature failure, increased maintenance, and operational downtime.

A common error is underestimating the abrasiveness of the solids in the slurry. Materials like sand, gravel, crushed ore, or tailings can wear down pump components quickly if not accounted for during selection. Choosing a submersible slurry pump without proper wear-resistant features, such as high-chrome impellers or abrasion-resistant liners, often results in reduced lifespan and more frequent part replacements.

Another pitfall is selecting a pump based solely on flow rate without considering slurry density. While gallons per minute is an important metric, it doesn’t reflect the full load a pump will experience. Slurries with high solids content are heavier and more viscous, placing greater stress on the motor and impeller. A properly sized submersible slurry pump must account for both flow and the physical properties of the material being pumped.

Choosing the wrong pump type is another issue. A hydraulic submersible slurry pump is better suited for mobile or remote operations where high torque and rugged construction are essential. In contrast, an electric submersible slurry pump is ideal for fixed installations with stable power availability and a need for energy efficiency. Using the wrong type for the application can lead to operational inefficiencies, limited mobility, or inadequate power delivery.

Lastly, ignoring material compatibility and wear resistance is a costly mistake. Not all pumps are built to handle chemical exposure or extreme abrasion. For example, pumping acidic or corrosive slurries with standard cast iron components can result in rapid corrosion. Whether using a hydraulic submersible slurry pump or an electric submersible slurry pump, selecting materials that match the chemical and physical nature of the slurry is critical to maintaining pump integrity and avoiding early failure.

Maintenance Considerations for Long-Term Performance

Regular maintenance is essential to keep a submersible slurry pump operating efficiently in abrasive and high-solid environments. Without a proactive maintenance plan, even the most robust pump can suffer from premature wear, unexpected downtime, and costly repairs. Implementing best practices tailored to the specific pump type—whether a hydraulic submersible slurry pump or an electric submersible slurry pump—helps extend service life and ensures consistent performance.

Routine inspections and scheduled part replacements are the foundation of effective maintenance. Critical components such as impellers, wear plates, and seals should be visually inspected at defined intervals based on usage intensity and slurry abrasiveness. Replacing worn components before failure helps avoid major system breakdowns and maintains optimal pump efficiency.

Monitoring seals and impellers is particularly important. The mechanical seals on a submersible slurry pump are exposed to high levels of grit, vibration, and pressure. A failing seal can allow slurry ingress, leading to motor or hydraulic system contamination. Similarly, worn impellers reduce pumping capacity and increase energy consumption. Early detection of wear patterns allows operators to plan repairs and avoid emergency shutdowns.

Flushing procedures are crucial to prevent buildup and corrosion inside the pump. After each shift or project cycle, especially in high-solid or chemically active applications, the submersible slurry pump should be flushed with clean water or a suitable neutralizing solution. This clears out residual slurry, reduces sediment buildup, and protects internal components from chemical attack or scaling. In hydraulic submersible slurry pumps, flushing should also include checking hydraulic lines for contamination and ensuring the fluid reservoir is clean and properly filled.

Specific maintenance practices vary by pump type. Hydraulic submersible slurry pumps require additional attention to the hydraulic system, including checking for leaks, inspecting hoses and fittings, and maintaining appropriate fluid levels and cleanliness. Electric submersible slurry pumps require inspection of electrical connections, cable integrity, insulation resistance, and thermal protection systems. Keeping cooling jackets and motor housings free from debris and buildup is essential to avoid overheating in electric models, especially in shallow or warm environments. By adapting maintenance routines to match the equipment’s configuration and usage, operators can achieve reliable, long-term performance from any submersible slurry pump.

Conclusion

Handling abrasive solids demands more than just a powerful pump—it requires the right submersible slurry pump tailored to the job’s unique challenges. From impeller design and material durability to seal protection and system configuration, every element plays a role in achieving reliable, long-term performance. Whether choosing a hydraulic submersible slurry pump for its torque and mobility or an electric submersible slurry pump for energy-efficient, stationary operation, informed selection and maintenance are key. By following best practices in sizing, installation, and upkeep, operators can ensure maximum productivity and longevity in even the most demanding slurry environments.