Keep Industrial and Manufacturing Operations Flowing in Texas with Proven Dredging Solutions

Sediment removal, waste lagoon maintenance, and slurry management for plants, mills, and heavy industrial sites.

Lone Star Dredge Services delivers rugged, high-performance dredging systems tailored for industrial and manufacturing environments. From processing plant byproduct ponds to sediment-choked outfalls and containment basins, our solutions support efficient waste handling, minimize downtime, and help facilities meet environmental standards. Whether you operate a paper mill, food processing plant, chemical facility, or foundry, we offer scalable dredging services that integrate seamlessly into your operations.

Key Challenges in Industrial & Manufacturing

Sludge and Byproduct Accumulation

Process water ponds, clarifiers, and holding basins accumulate heavy, abrasive sludge that requires high-solids handling and clog-resistant pumping.

Regulatory Compliance

Facilities must adhere to strict discharge, containment, and NPDES requirements for sediment, sludge, and wastewater.

Limited Operational Disruption

Downtime equals lost production—dredging solutions must be fast, reliable, and non-invasive to operations.

Hazardous and Viscous Materials

Industrial waste often includes corrosive, high-density, or chemically active materials not suitable for conventional dredging systems.

Our Solutions

We help industrial facilities maintain efficient, clean, and compliant operations with specialized dredging services for sludge, slurry, and water management systems.

Specialized Dredging Services

Wastewater and Process Pond Dredging

Removes accumulated solids from primary and secondary treatment ponds to restore flow and function.

Slurry Pit and Settling Tank Maintenance

Handles dense, abrasive mixtures produced by manufacturing processes.

Industrial Lagoon and Clarifier Cleaning

Maintains capacity and treatment performance in lagoons, clarifiers, and containment basins.

Emergency Spill Containment and Cleanup

Rapid deployment to remove contaminated sediment from ponds or drainage channels.

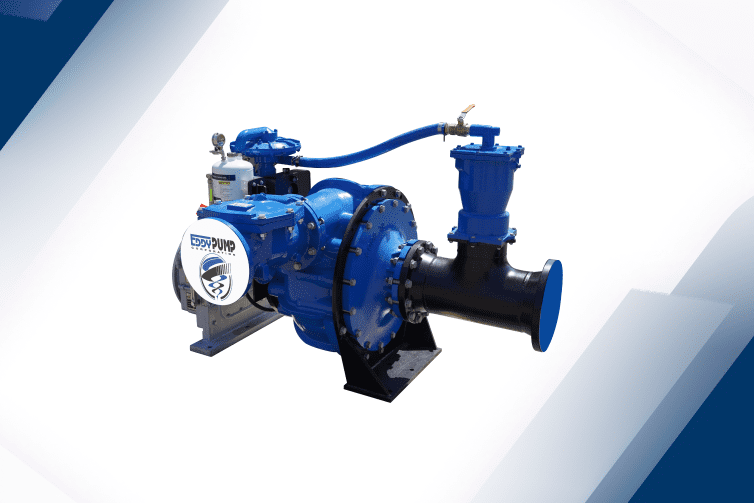

Equipment Highlights

Our equipment is engineered for abrasive, corrosive, and high-solids environments commonly found in industrial settings.

Excavator Pump Attachments

- Easily mounted to in-plant or contractor-owned excavators

- Perfect for sludge basins, settling ponds, and lime or ash pits

- Multiple nozzle and cutter options for varied material types

- Liner-safe designs for concrete or geomembrane basins

Cable-Deployed Dredge Pumps

- Excellent for deep tanks, high-wall pits, or inaccessible ponds

- Can handle solids up to 12" in diameter and 70% by weight

- Deployed using overhead cranes or fixed gantry systems

Remote-Operated Dredges

- Ideal for enclosed, hazardous, or limited-access zones

- Fully remote dredging with real-time monitoring

- Eliminates the need for manned equipment near dangerous materials

Self-Priming Slurry Pumps

- Quickly drain pits, tanks, or washdown areas

- Electric and diesel units available for indoor or outdoor deployment

- High-solids throughput and clog-resistant design

Dewatering Solutions

- On-site sludge drying using geotextile tubes or mechanical dewatering

- Reduces waste volume and hauling costs

- Compliant with solid waste disposal standards

Why Choose Us for Industrial Dredging

Built for Industry

Our dredging systems are designed to handle grit, ash, sludge, lime, and more with minimal wear and high durability.

Customizable Integration

We work with plant engineers to plan dredging around operations, ensuring minimal interference.

Safety and Compliance First

We operate under OSHA protocols and assist with EPA/NPDES reporting requirements.

24/7 Emergency Response Available

When unplanned maintenance or environmental incidents occur, we mobilize quickly.

Turnkey Solutions

From sediment surveys and waste profiling to dredging and off-site disposal, we manage the complete process.