Lakes play vital roles in ecosystems, recreation, and water management. However, over time, they accumulate sediment, organic debris, and pollutants that can degrade water quality, reduce depth, and hinder navigation. Lake dredging is an essential process for maintaining a healthy and functional water body. Removing accumulated materials from the lakebed helps restore aquatic habitats, improve water circulation, and prevent excessive weed growth.

Effective lake dredging equipment is crucial for ensuring successful sediment removal while minimizing environmental impact. There are two primary dredging methods: hydraulic and mechanical. Each approach has its advantages and is suited for different project requirements, depending on factors like sediment type, lake size, and disposal methods.

Hydraulic dredging relies on high-powered pumps to remove and transport sediment as a slurry, making it ideal for large-scale operations that require continuous material removal with minimal disruption. On the other hand, mechanical dredging uses heavy machinery, such as clamshell buckets, excavators, or draglines, to scoop and remove sediment physically. Thus, it is well-suited for projects requiring precision and the removal of dense or compacted material.

Choosing the right lake dredging equipment is essential for efficiently and cost-effectively achieving project goals. This article explores the key differences between hydraulic and mechanical dredging, helping decision-makers determine the best method for a lake based on specific environmental and operational needs.

Understanding Lake Dredging

Lake dredging is the process of removing accumulated sediment, organic debris, and pollutants from the bottom of a lake to restore its depth, improve water quality, and maintain ecological balance. Over time, lakes naturally fill with silt, sand, and decomposing organic matter, leading to reduced water volume, poor circulation, and increased algae growth. Without proper maintenance using specialized lake dredging equipment, these issues can negatively impact aquatic life, water quality, and recreational use.

There are several critical reasons to dredge a lake, each addressing specific environmental and operational concerns:

- Sediment Removal: Sediment buildup can lead to excessive shallowing, reducing water storage capacity and increasing the risk of algal blooms and oxygen depletion. Lake dredging equipment effectively removes these deposits, restoring the lake’s depth and preventing further deterioration.

- Water Quality Improvement: Over time, lakes accumulate pollutants, excess nutrients, and decaying organic material, contributing to water contamination. Dredging helps eliminate harmful substances, reduce phosphorus levels, and mitigate the risk of toxic algae outbreaks that can endanger aquatic life and human health.

- Habitat Restoration: A heavily silted lake can suffocate fish populations and disrupt natural ecosystems. Dredging re-establishes deeper, oxygen-rich water zones, creating healthier conditions for fish and other aquatic species. It also supports wetland restoration by managing sediment flow and promoting natural water filtration.

- Navigation Enhancement: Excessive sedimentation can make boating, fishing, and other recreational activities difficult or even impossible. Removing built-up material allows for safer and more accessible waterways, ensuring continued use for tourism, transportation, and local industries.

- Flood Control: Sediment accumulation can restrict water flow, increasing the likelihood of flooding during heavy rains or seasonal storms. By using lake dredging equipment to remove obstructions, water bodies can better manage inflows, reducing the risk of overflow and damage to surrounding areas.

Proper lake maintenance requires an efficient and strategic approach to dredging. Whether using hydraulic or mechanical methods, selecting the right equipment is crucial for achieving long-term environmental and operational benefits while preserving the integrity of the water body.

Overview of Hydraulic Dredging

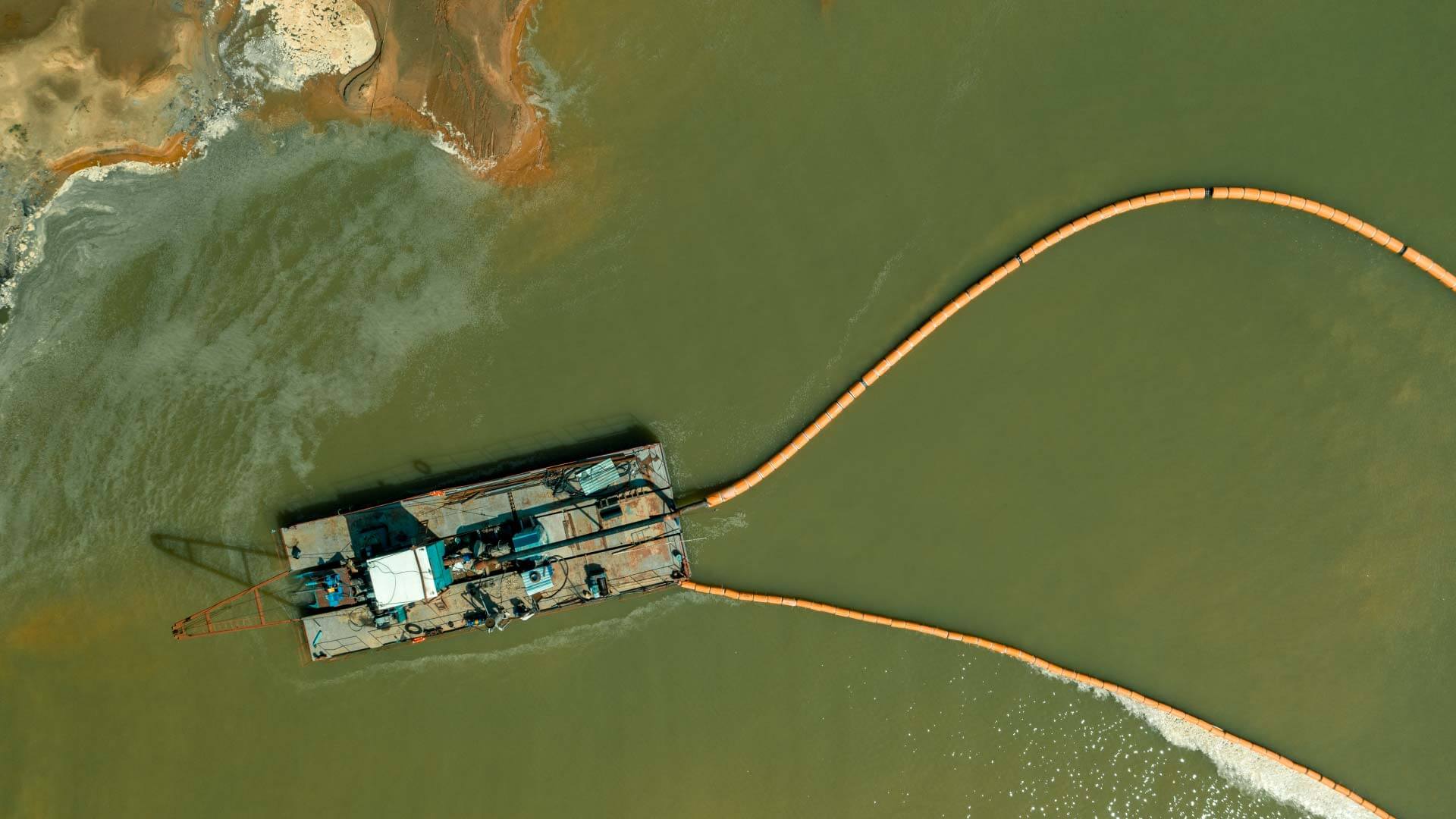

Hydraulic dredging is a highly efficient method for removing sediment from lakes and other water bodies. It uses powerful pumps to transport material in the form of a slurry. The process involves breaking up accumulated sediment with a dredge head and mixing it with water before pumping it through pipelines for transport to a designated disposal or dewatering site. Ideal for large-scale projects, hydraulic dredging allows for continuous material removal with minimal disruption to the aquatic environment.

Types of Hydraulic Lake Dredging Equipment

Several types of lake dredging equipment are used in hydraulic dredging, each designed to handle different sediment conditions and project requirements:

- Cutter-suction dredges(CSDs): Equipped with a rotating cutter head, these dredges break up compacted sediment before suctioning it into a pipeline for transport. They are commonly used for large-scale projects that require precise and deep dredging.

- Auger Dredges: This type of dredge features a horizontal rotating auger and efficiently removes fine sediments and organic material with minimal turbidity. It is often used for environmental dredging and projects that require minimal water disturbance.

- Slurry Pumps: These high-powered pumps are essential for transporting dredged material through long pipeline systems. Often paired with booster pumps, they allow for efficient sediment transfer over extended distances.

Key Advantages of Hydraulic Dredging

- Efficient for Large-Scale Sediment Removal: Hydraulic dredging is ideal for deep lakes or projects requiring the removal of vast amounts of sediment over a short period. It provides continuous, high-volume excavation without the need for frequent equipment repositioning.

- Minimal Disruption to Aquatic Life: Hydraulic dredging reduces harm to fish, plants, and other aquatic organisms compared to traditional excavation methods. Sediment is suctioned directly from the lakebed with minimal mechanical disturbance.

- Continuous Dredging Operation: Unlike mechanical dredging, which involves repeated excavation and transport, hydraulic dredging operates as a streamlined system, allowing for uninterrupted material removal and transport.

- Suitable for Fine Sediments and Soft Materials: Hydraulic dredging is particularly effective for removing loose, fine-grained sediments such as silt, clay, and organic debris, which can be difficult to manage using mechanical methods.

Potential Drawbacks of Hydraulic Dredging

- Requires Specialized Pumping Equipment: Hydraulic dredging relies on high-powered pumps, dredge heads, and pipelines, making it more equipment-intensive than traditional mechanical dredging. Proper setup and maintenance are necessary to ensure efficiency.

- Sediment Needs to Be Dewatered Before Disposal: Since hydraulic dredging produces a slurry, the extracted material must undergo dewatering before disposal or reuse. This process may require additional infrastructure, such as geotextile tubes or settling ponds.

- Limited Effectiveness for Heavy Debris and Large Objects: While hydraulic dredging is excellent for fine sediments, it is less effective at handling heavy debris, such as rocks, logs, or compacted material, which may require mechanical excavation.

Hydraulic dredging is a powerful solution for maintaining and restoring lakes. It offers efficient sediment removal with minimal environmental impact. Selecting the right lake dredging equipment ensures optimal results based on project size, sediment composition, and disposal requirements.

Overview of Mechanical Dredging

Mechanical dredging is a method of lake dredging that involves physically excavating and removing sediment, debris, and other materials from the lakebed using heavy machinery. Unlike hydraulic dredging, which relies on pumps and slurry transport, mechanical dredging lifts material directly from the bottom and loads it onto barges or trucks for immediate disposal. This method is particularly effective for removing compacted sediment, large debris, and hard materials that may be difficult to transport through a slurry system.

Types of Mechanical Lake Dredging Equipment

Several types of lake dredging equipment are used in mechanical dredging, each suited for different project conditions and material types:

- Clamshell Dredges: These dredges use a large bucket operated by a crane or excavator to scoop and lift sediment. They are ideal for targeted dredging in harbors, marinas, and confined areas where precise removal is needed.

- Backhoe Dredges: These dredges, which feature a hydraulic arm with a digging bucket, are commonly used for nearshore dredging projects and areas with compacted or rocky sediment. They provide excellent excavation control and precision.

- Draglines: These machines use a long boom and wire rope system to drag a bucket along the lakebed, collecting sediment and debris. Draglines are highly effective for reaching deeper areas and working in environments with unstable soil.

- Bucket-Ladder Dredges: Equipped with a series of buckets mounted on a rotating chain, bucket-ladder dredges continuously lift and transport sediment. This method is well-suited for large-scale projects requiring significant material removal.

Key Advantages of Mechanical Dredging

- Effective for Removing Heavy Debris and Compacted Sediment: Mechanical dredging excels in removing dense, compacted materials, including rocks, logs, and industrial waste, which may be challenging for hydraulic dredging systems.

- Precise Dredging in Small, Targeted Areas: Unlike hydraulic dredging, which removes sediment as a slurry, mechanical dredging allows for pinpoint accuracy, making it ideal for projects in marinas, docks, and environmentally sensitive areas.

- Immediate Removal and Disposal of Sediment: Mechanical dredging lifts sediment directly onto transport vessels or trucks, streamlining the process by allowing the removal and disposal of the material without requiring dewatering or settling ponds.

Potential Drawbacks of Mechanical Dredging

- Can Be Disruptive to the Aquatic Ecosystem: The physical excavation process disturbs the lakebed, potentially harming aquatic habitats, stirring up sediments, and increasing water turbidity, which may impact water quality.

- Mechanical dredging is typically more labor-intensive and Costly: Mechanical dredging often requires multiple pieces of heavy equipment, transportation logistics, and on-site labor, making it a more expensive option for large-scale projects.

- Less Effective for Fine Sediments and Deep-Water Applications: While mechanical dredging is excellent for compacted material, it is less efficient for removing fine silt and clay, especially in deep-water environments where hydraulic dredging is often more effective.

Mechanical dredging remains a valuable method for dredging a lake, especially when dealing with hard-to-remove materials or areas requiring precise excavation. Selecting the right lake dredging equipment depends on the project scope, sediment composition, and environmental considerations.

Key Factors to Consider When Choosing Between Hydraulic and Mechanical Dredging

Selecting the right lake dredging equipment depends on several critical factors, including project scope, sediment type, environmental impact, budget, and efficiency. Both hydraulic and mechanical dredging offer unique advantages and challenges, so it is essential to evaluate these factors before choosing the best method for effectively dredging a lake.

Lake Size and Depth

The size and depth of a lake play a significant role in determining which dredging method is most suitable:

- Hydraulic dredging is ideal for large lakes with deep water and extensive sediment buildup. It allows for continuous sediment removal without frequent repositioning, making it more efficient for large-scale operations.

- Mechanical dredging is better suited for smaller, shallow lakes or targeted dredging projects where precision is required. However, due to equipment limitations, it may become inefficient for deep-water applications.

Type of Sediment to Be Removed

The composition of the sediment directly influences the choice of lake dredging equipment:

- Hydraulic dredging is most effective for soft, fine-grained sediments such as silt, clay, and organic debris. It efficiently removes loose materials while minimizing turbidity.

- Mechanical dredging is better suited for compacted, coarse, or debris-laden sediments, including sand, gravel, logs, and rocks. It can handle denser materials that hydraulic dredging may struggle to transport through a slurry system.

Environmental Impact

When considering the environmental effects of lake dredging, the level of disturbance to aquatic ecosystems is a crucial factor:

- Hydraulic dredging is generally less disruptive. It removes sediment with minimal direct impact on the lakebed and aquatic life. The suction process reduces habitat destruction and limits sediment resuspension.

- Mechanical dredging can be more invasive, as it physically excavates the lakebed, potentially disturbing fish populations, aquatic plants, and water quality. Increased turbidity and habitat disruption are common concerns.

Cost Considerations

Budget constraints and cost-effectiveness must be evaluated when choosing lake dredging equipment:

- Hydraulic dredging typically requires a higher initial investment due to the specialized equipment and pipeline infrastructure. However, due to its efficiency and continuous operation, it is often more cost-effective for large-scale projects.

- Mechanical dredging may have lower upfront equipment costs but can be more expensive in terms of labor, sediment transport, and disposal. The need for frequent repositioning and excavation makes it less economical for large projects.

Project Timeline and Efficiency

Dredging projects vary in duration depending on the method used:

- Hydraulic dredging is highly efficient for continuous sediment removal, reducing overall project timelines for large lakes. Since the material is pumped directly to disposal sites, it eliminates the need for manual transport.

- Mechanical dredging requires stopping and starting as sediment is excavated, loaded, and transported. This process increases the time required for completion, making it less efficient for large-scale projects.

Dewatering and Sediment Disposal Needs

How dredged material is handled post-extraction is a key consideration:

- Hydraulic dredging produces a sediment-water slurry that must be dewatered before disposal. This requires additional infrastructure such as geotextile tubes, settling ponds, or mechanical dewatering systems.

- Mechanical dredging removes sediment in a solid form, eliminating the need for extensive dewatering. However, it requires more logistical planning for sediment transport and disposal.

Choosing between hydraulic and mechanical dredging depends on a combination of these factors. The right lake dredging equipment will maximize efficiency, minimize environmental impact, and ensure successful sediment removal based on project-specific needs.

Conclusion: Which Lake Dredging Equipment is Right for Your Project?

Several factors, including project size, sediment composition, environmental impact, and budget constraints, influence the choice of lake dredging equipment. Both hydraulic and mechanical dredging offer distinct advantages, and selecting the most suitable method is crucial for achieving project efficiency and environmental sustainability.

Key Differences Between Hydraulic and Mechanical Dredging

- Hydraulic dredging uses powerful pumps to remove sediment in the form of a slurry, making it ideal for large-scale projects and fine sediments like silt and clay. It minimizes environmental disturbance and operates continuously but requires dewatering infrastructure.

- Mechanical dredging physically excavates sediment using clamshells, backhoes, or draglines. It is most effective for compacted or debris-heavy material and provides immediate removal, but it can disrupt aquatic ecosystems and require sediment transport logistics.

Recommendations Based on Project Needs

- For large lakes with deep water and fine sediments, → hydraulic dredging is the most efficient choice because it can remove vast amounts of material with minimal disruption.

- For small, shallow lakes or targeted dredging projects,→ Mechanical dredging offers precision and is well-suited for marina maintenance, dock restoration, or localized sediment removal.

- For environmentally sensitive areas → Hydraulic dredging reduces habitat disturbance and water turbidity, making it preferable for ecological restoration projects.

- For projects involving heavy debris and compacted materials, → Mechanical dredging is the better option since it can handle dense, coarse materials that hydraulic systems struggle with.

- For cost-conscious projects → Hydraulic dredging is more cost-effective for large-scale operations, while mechanical dredging may be more economical for smaller, localized projects.

Selecting the right lake dredging equipment requires a careful assessment of the project’s scope and environmental considerations. By evaluating factors like lake size, sediment type, and disposal requirements, stakeholders can ensure an efficient and effective dredging solution that meets both operational and ecological goals.